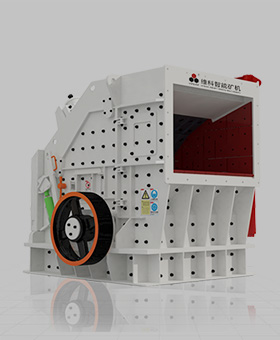

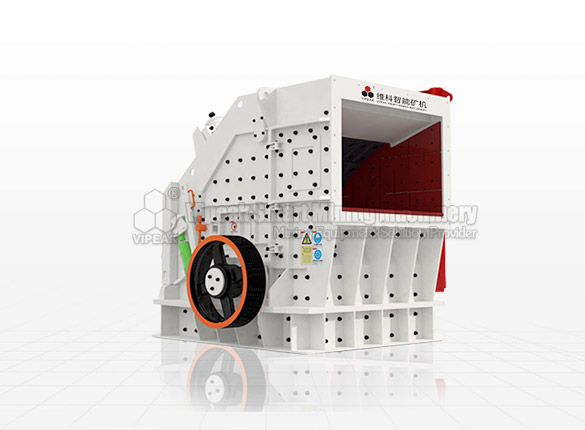

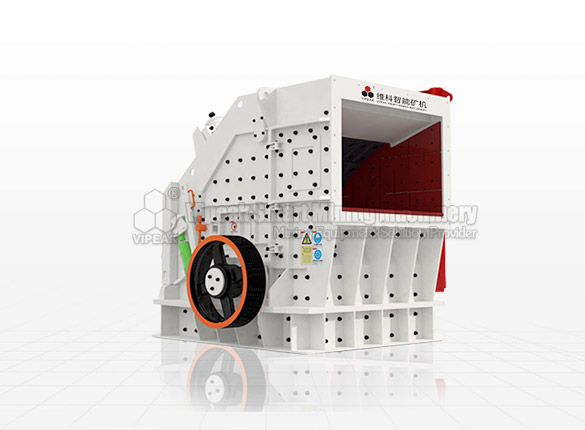

PFS Impact Crusher a new type impact crusher developed by Vipeak. It adopts hydraulic top device and maintenance lifting design can achieve the change of board hammer and other wearing parts in a short time which reduce halt and maintenance time and cost of maintenance. The bearing pedestal of PFS impact crusher adopts overall forging steel.

Limestone, calcite, coal ash, kaolin, calcium carbonate, gangue, gypsum, grain slag, superfine slag powder, coal dust, bentonite, barite, marble, talc, refractory material

Cement, silicate product, new building materials, refractory material, chemical fertilizer, nonferrous and ferrous metal beneficiation and glass ceramic industries.

| Model |

Output size(mm)

|

Feeding

size (mm) |

Capacity(t/h) | Power(kw) | Dimension(L×W×H)mm |

| PFS1010 | 20-100 | 600 | 100-200 | 90-110 |

2800×1925×2305

|

| PFS1210 | 20-100 | 900 | 140-285 | 110-160 | 2871×1967×2600 |

| PFS1214 | 20-100 | 900 | 200-400 | 160-200 | 2871×2307×2600 |

| PFS1317 | 20-200 | 950 | 250-500 | 200-315 | 3175×2781×2800 |

| PFS1420 | 20-200 | 1000 | 400-600 | 315-375 | 3582×3205×3118 |

| PFS1620 | 20-200 | 1200 | 550-700 | 400-500 | 4056×3395×3356 |