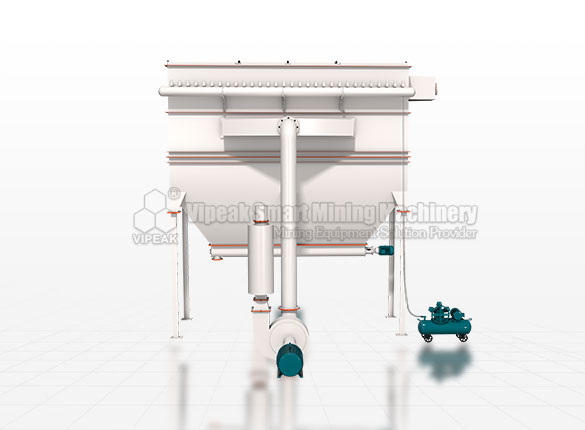

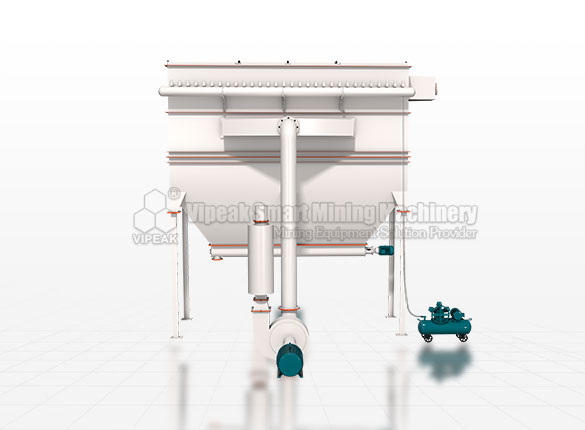

Pulse bag dust catcher is high efficiency energy saving machinery designed by our researcher after several years mining crushing and grinding dedusting and ore powder collecting experience, it can adapted strict dust discharging standard domestic and overseas.

Limestone, calcite, coal ash, kaolin, calcium carbonate, gangue, gypsum, grain slag, superfine slag powder, coal dust, bentonite, barite, marble, talc, refractory material

Cement, silicate product, new building materials, refractory material, chemical fertilizer, nonferrous and ferrous metal beneficiation and glass ceramic industries.

|

Model

|

Air Capacity

|

Filtrate Air

|

Filtering

Quantity

(Pcs)

|

Pulse

Valve

(Pcs)

|

Power of

Air Blower

(KW)

|

| DMC36 | 1680-2680 | 30 | 36 | 6 | 2.2 |

| DMC48 | 2500-3500 | 40 | 48 | 6 | 2.2 |

| DMC64 | 3500-5000 | 64 | 64 | 8 | 3 |

| DMC80 | 4500-6000 | 80 | 80 | 10 | 5.5 |

| DMC96 | 5500-7000 | 96 | 96 | 12 | 5.5 |

| DMC112 | 6500-8500 | 112 | 112 | 14 | 7.5 |

| DMC160 | 9600-16000 | 160 | 160 | 20 | 11 |

|

Model

|

Air Capacity

|

Filtrate Air

|

Filtering

Quantity

(Pcs)

|

Resistance

(Pcs)

|

| PPC96-5 | 33400 | 480 | 480 | 1470-1770 |

| PPC96-6 | 40100 | 576 | 576 | 1470-1770 |

| PPC96-7 | 46800 | 672 | 672 | 1470-1770 |

| PPC96-8 | 53510 | 768 | 768 | 1470-1770 |

| PPC96-9 | 61400 | 864 | 864 | 1470-1770 |

| PPC96-2*5 | 66900 | 960 | 960 | 1470-1770 |

| PPC96-2*6 | 80700 | 1152 | 1152 | 1470-1770 |

| PPC96-2*7 | 94100 | 1344 | 1344 | 1470-1770 |