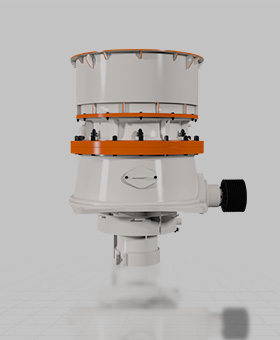

Single cylinder hydraulic cone crusher represents world's most advanced crushing technology widely used in metal and non-metallic mineral cement sand and metallurgical industries for crushing fine crushing and ultra fine crushing. It has many advantages like high efficiency crushing low production cost easy to maintain good product shape suitable for fine crushing and ultra fine crushing of minerals.

Limestone, granite, marble, basalt, iron ore, cobble, shale, bluestone, coal, pebbles, etc.

Construction waste ,metallurgy, building, water and electricity, transportation, chemical industry, and building materials industry

| Model | Cavity | Max feeding size(mm) | Mini discharge opening size(mm) | Power(kw) | Capacity(Capacity ) |

| HST100 | S1(Extra Coarse) |

240

|

22 | 90 | 85-170 |

| S2(Medium coarse) | 200 | 19 | 70-130 | ||

| H1(Fine) | 135 | 10 | 46-130 | ||

| H2(Medium fine)(Fine) | 65 | 8 | 35-80 | ||

| H3(Extra fine)(Fine) | 38 | 4 | 27-60 | ||

| HST160 | S1(Extra Coarse) | 360 | 25 | 132 | 120-345 |

| S2(Medium coarse) | 300 | 22 | 105-305 | ||

| H1(Fine) | 185 | 13 | 66-210 | ||

| H2(Medium fine)(Fine) | 90 | 10 | 65-165 | ||

| H3(Extra fine)(Fine) | 50 | 6 | 48-105 | ||

| HST250 | S1(Extra Coarse) | 450 | 35 | 220 | 255-605 |

| S2(Medium coarse) | 400 | 29 | 215-515 | ||

| H1(Fine) | 215 | 16 | 110-395 | ||

| H2(Medium fine)(Fine) | 110 | 13 | 115-340 | ||

| H3(Extra fine)(Fine) | 70 | 8 | 90-255 | ||

| HST315 | S1(Extra Coarse) | 560 | 41 | 315 | 335-1050 |

| S2(Medium coarse) | 500 | 38 | 305-895 | ||

| H1(Fine) | 275 | 16 | 170-665 | ||

| H2(Medium fine)(Fine) | 135 | 16 | 190-505 | ||

| H3(Extra fine)(Fine) | 65 | 13 | 205-320 | ||

| HST450 | S1(Extra Coarse) | 560 | 56 | 450 | 300-1300 |

| S2(Medium coarse) | 465 | 56 | 400-1200 | ||

| HST560 | H1(Fine) | 300 | 22 | 560 | 448-1512 |

| H2(Medium fine)(Fine) | 155 | 19 | 400-1372 | ||

| H3(Extra fine)(Fine) | 80 | 10 | 280-775 | ||

| HST750 | H1(Fine) | 370 | 25 | 750 | 480-2500 |

| H2(Medium fine)(Fine) | 195 | 22 | 552-1604 | ||

| H3(Extra fine)(Fine) | 85 | 10 | 364-883 |