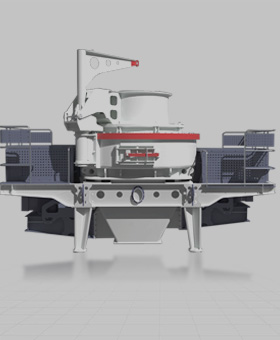

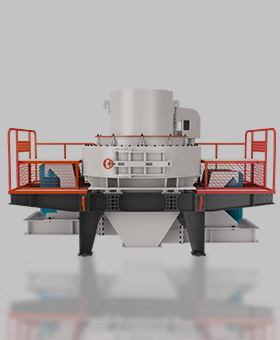

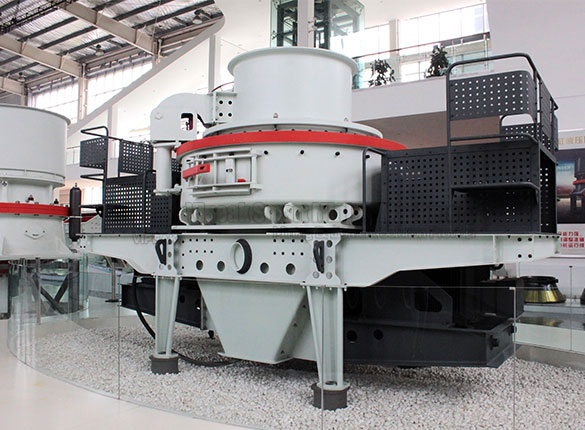

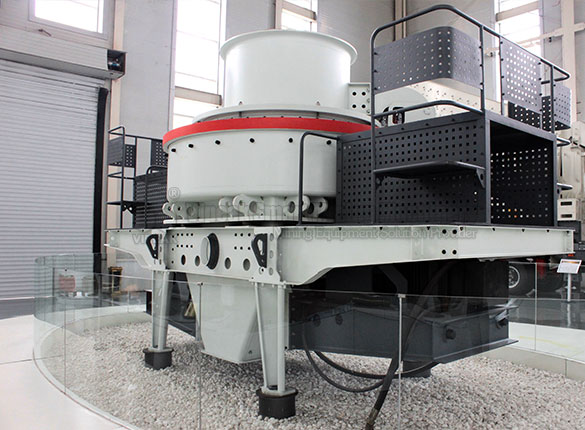

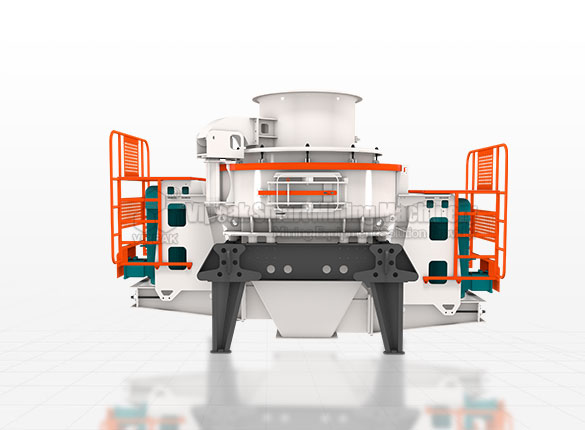

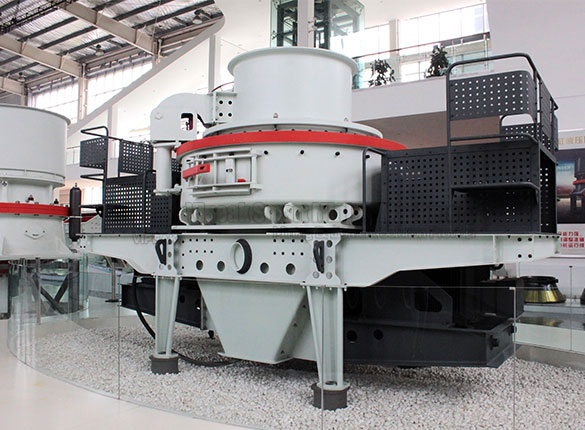

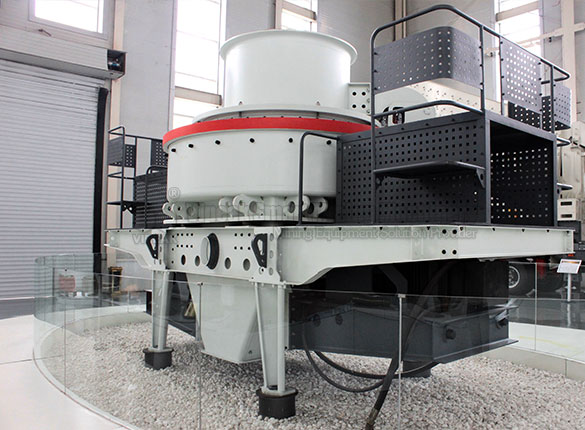

The new series of 5X sand making machine set three kinds of crushing patterns .5X sand making equipment is widely used in a variety of metals and non-metallic minerals cement refractories abrasives glass raw materials construction aggregate sand mechanism metallurgy and other industries.

Limestone, calcite, coal ash, kaolin, calcium carbonate, gangue, gypsum, grain slag, superfine slag powder, coal dust, bentonite, barite, marble, talc, refractory material

Cement, silicate product, new building materials, refractory material, chemical fertilizer, nonferrous and ferrous metal beneficiation and glass ceramic industries.

| Model | Capacity(t/h) | Optimum feed size(mm) | Speed(r/min) |

Double

motor power

|

Weight |

Power

supply

|

Dimension(L×W×H) | ||

|

Center

and ring feeding

|

Center

feeding

|

Soft

material

|

Hard

material

|

||||||

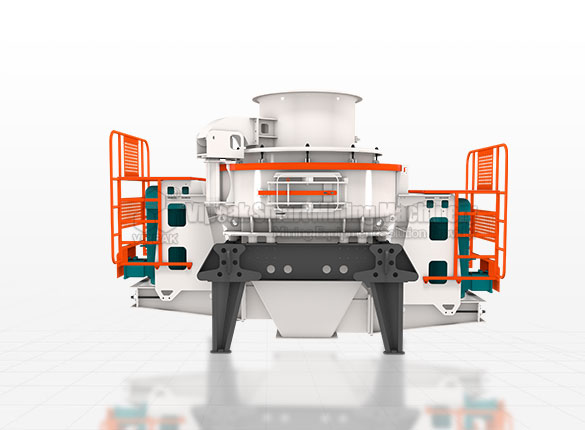

| 5X7615 | 150-280 | 70-140 | 35 | 30 | 1700-1900 | 150 | 10 | 380v,50hz | 4100×2322×2459 |

| 5X8522 | 240-380 | 120-190 | 40 | 35 | 1500-1700 | 220 | 12.5 | 4500×2478×2658 | |

| 5X9532 | 350-540 | 180-280 | 45 | 40 | 1300-1510 | 320 | 14.5 | 4800×2571×2893 | |

| 5X1145 | 500-640 | 250-360 | 50 | 45 | 1100-1310 | 440 | 19 | 5500×2799×3320 | |

|

Hydraulic

lubrication

station

|

Power(kW) | Safety | Flow capacity | Oil tank heater power | |||||

| 0.75 | Automatic stop working when weak oil flow or low hydraulic pressure,Air cooling system,Start heating system automatically in winter. | 4-16L | 4kW | ||||||