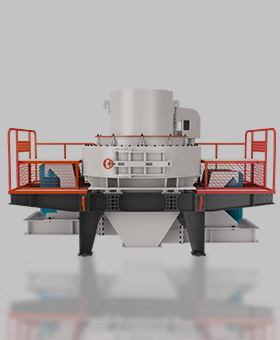

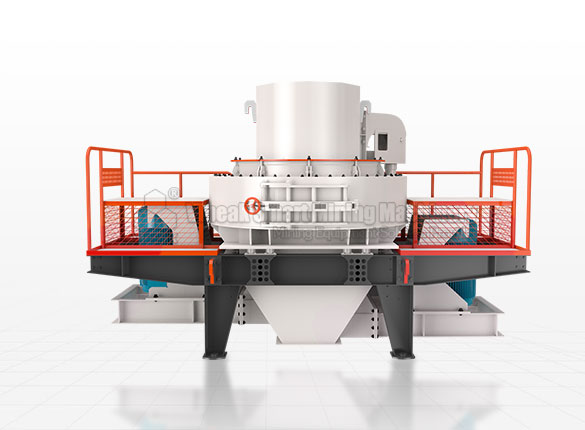

The unique hydraulic open top system can make it convenient and quick to remove upper cover Even one person can also easily accomplish it,and thus shortening the maintenance downtime. Simple hoisting device can make it convenient for users to lift rotor and bearing housing assembly.make maintenance more conveient,at same time saved the cost and time of maintenance.

Limestone, calcite, coal ash, kaolin, calcium carbonate, gangue, gypsum, grain slag, superfine slag powder, coal dust, bentonite, barite, marble, talc, refractory material

Cement, silicate product, new building materials, refractory material, chemical fertilizer, nonferrous and ferrous metal beneficiation and glass ceramic industries.

| Model | Capacity(t/h) | Optimum feed size(mm) | Speed(r/min) |

Double

motor power

|

Weight |

Power

supply

|

Power

supply

|

Dimension(L×W×H) | ||

|

Center

and ring feeding

|

Center

feeding

|

Soft

material

|

Hard

material

|

|||||||

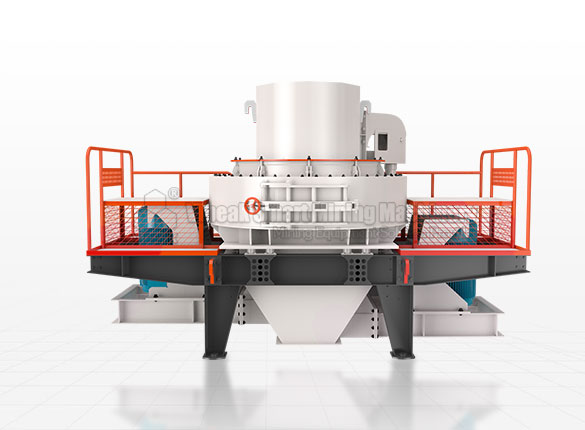

| VSI7611 | 120-180 | 60- 90 | 35 | 30 | 1700-1890 | 110 | 11.8 | 380v,50hz | 2×0.25kW | 3700×2150×2100 |

| VSI8518 | 200- 260 | 100- 130 | 40 | 35 | 1520-1690 | 180 | 14.5 | 4140×2280×2425 | ||

| VSI9526 | 300- 380 | 150- 190 | 45 | 40 | 1360-1510 | 264 | 17.8 | 4560×2447×2778 | ||

| VSI1140 | 450- 520 | 225- 260 | 50 | 45 | 1180-1310 | 400 | 25.6 | 5000×2700×3300 | ||

|

Hydraulic

lubrication

station

|

Power(kW) | Safety | Flow capacity | Oil tank heater power | ||||||

| 0.75 | Automatic stop working when weak oil flow or low hydraulic pressure,Air cooling system,Start heating system automatically in winter. | 4-16L | 4kW | |||||||