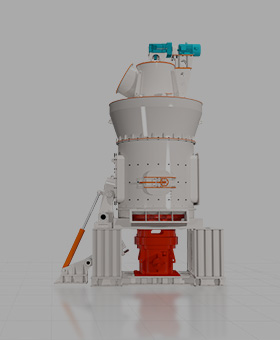

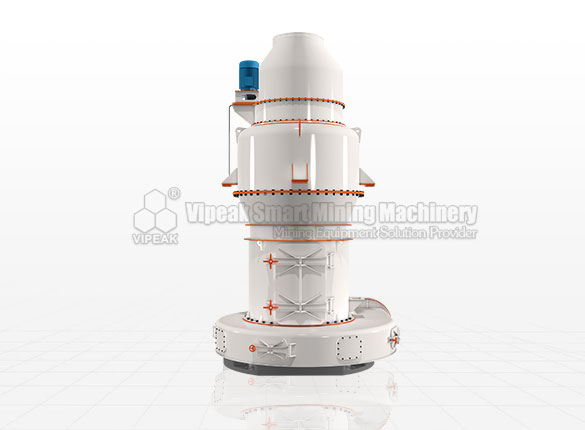

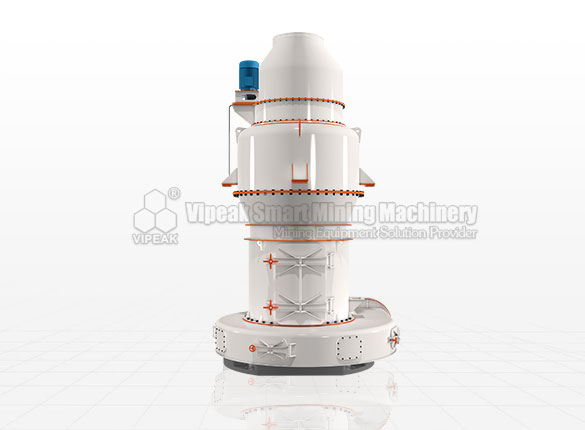

YGM-Q4 Series European Type Strength Grinding Mill is completely updated high-end high capacity energy-saving environmental and strong grinding equipment.It is widely used in the fields of mining construction materials electric power road and bridge building coal metallurgy chemical ceramics fireproof industries and so on.

Limestone, calcite, fly ash, calcium carbide, kaolin, calcium carbonate, coal gangue, gypsum, grain slag, ore slag, coal dust, bentonite, barite, marble, talc, refractory material

mining industry, chemical engineering, construction material and metallurgy industry over 280 kinds material process

|

Model

|

Ring

Diameter

(mm)

|

Quantity of

Rollers

(pcs.)

|

Speed of

MainMill

(r/min)

|

Max.

Feeding

Size(mm)

|

The Final

Size

(mesh)

|

Capacity

(t/h)

|

External Dimension

(mm)

|

|

YGM95- Q4

|

950 | 4 | 132 | ≤25 | 80-800 | 0.5-6.5 | 7350×5900×7900 |

|

YGM110- Q4

|

1100 | 4 | 110-125 | ≤25 | 80-800 | 2-10 | 8425×7933×8642 |

| YGM130- Q4 | 1280 | 4 | 106 | ≤30 | 80-600 | 2-13.8 | 8000×8550×9700 |

| YGM138- Q4 | 1380 | 4 | 105 | ≤30 | 80-600 | 2.9-17.5 | 9700×8500×10200 |

| YGM160- Q4 | 1600 | 4 | 92 | ≤30 | 80-425 | 5-25 | 9230×10116×10510 |

| YGM178- Q4 | 1800 | 4 | 78 | ≤35 | 80-425 | 6.5-32 | 9368×11500×11000 |

| YGM190- Q4 | 1900 | 4 | 72 | ≤35 | 80-425 | 8.4-40 | 10465×11372×11500 |

| YGM218- Q4 | 2200 | 4 | 65 | ≤40 | 80-425 | 12-55 | 16000×17000×13500 |

|

Model

|

Main frame

Power

(KW)

|

Power of

Air Blower

(KW)

|

Power of

Classifier

(KW)

|

Model of Pulse

Dust Collector

|

Dust Catcher Power

(kw) Blower +

Air Compressor

|

Power of

Frequency feader

(kw)

|

| YGM95- Q4 | 37 | 30-37 | 5.5-11 | DMC36 | 3+4 | 0.15 |

| YGM110- Q4 | 55 | 55 | 7.5-11 | DMC88 | 7.5 | 0.15 |

| YGM130- Q4 | 75-90 | 75-90 | 18.5-22 | DMC36 | 3+4 | 3 |

| YGM138- Q4 | 90-110 | 110-132 | 22-30 | DMC48 | 3+4 | 4 |

| YGM160- Q4 | 132-160 | 160-200 | 30-37 | DMC64 | 5.5+5.5 | 5.5 |

| YGM178- Q4 | 185-200 | 200-220 | 37-45 | DMC96 | 7.5+7.5 | 5.5 |

| YGM190- Q4 | 220-250 | 220-250 | 45-55 | DMC96 | 7.5+7.5 | 5.5 |

| YGM218- Q4 | 355-400 | 355-400 | 75-90 | DMC200 | 18.5+18.5 | 7.5 |